Siemens NX

NX is a flexible software from SIEMENS with powerful CAD/CAM functions that enables seamless production from digital part models through NC programming to finished precision components. NX Tools is used in the FRAISA ToolSchool - a partnership with SIEMENS was therefore an obvious choice.

Functions & features

An interface is currently available to NX CAM users for the direct transfer of geometry and cutting data between FRAISA ToolExpert® and NX Tools.

By eliminating manual input, the entire work process is shorter, more efficient and less error-prone - the use of process-reliable data is thus noticeably simplified and improved.

The geometry and cutting data are available for the most of FRAISA milling and drilling tools.

Advantages

- Optimization of production processes

- Direct import, no more manual input

- High process reliability

- Simplified and efficient use

- Reduced susceptibility to errors

- Significant time savings

Step by step:

Generate Process-reliable geometry and cutting data

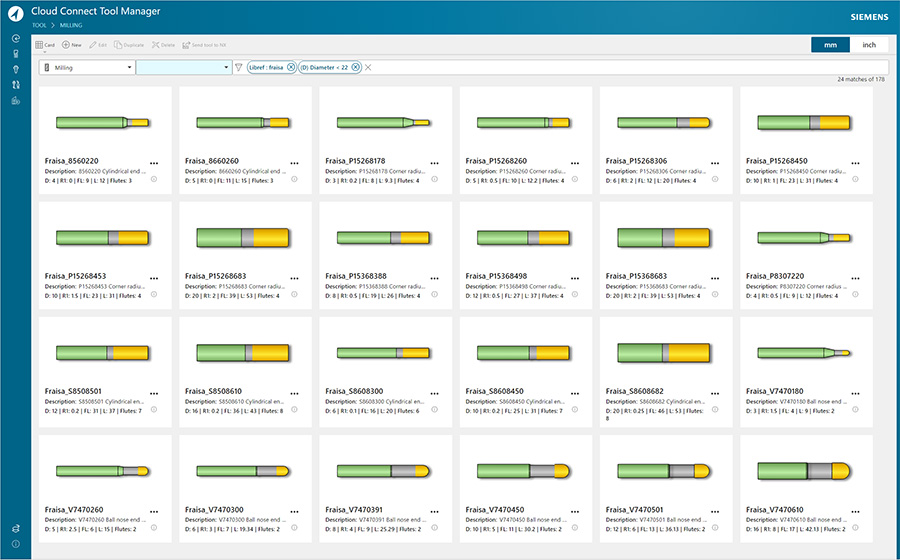

Call up FRAISA ToolExpert® from the NX Cloud Connect Tool Manager (customized NX/FRAISA ToolExpert® version)

Select the desired tool and “Send to NX Tool Only Product Data“ or Forward

Select the stock material

Select the application(2.5D/3D, Roughing/Finishing, Performance/Dynamic)

Click “Send to NX Tool” to display the geometry data including drawing and cutting data in the Cloud Connect Tool Manager

Add the geometry and cutting data to the tool overview or import into NX

Display the geometry data and consume cutting data in the selected project