ArCut X is a productivity booster for finishing with excellent surface quality

Do you finish flat surfaces with a ball nose end mill? Do you ever wonder why the machining times are so long? Then we’ve got great news for you! The new ArCut X tool concept from FRAISA has arrived!

ArCut X is a conical end mill whose curved surface area has a radius of curvature of up to 1,000 mm. Thanks to this large radius of curvature, it’s possible to realise larger step-over distances without any signifi cant impact on the theoretical scallop height. The result is highly precise surfaces with brilliant surface characteristics that can minimise the amount of time spent polishing. As the tip of the ArCut X milling cutter has a perfectly spherical form, it also offers all of the plus points of a robust ball nose end mill.

As such, FRAISA’s innovative ArCut X tool concept integrates great finishing performance with almost perfect surface qualities and is therefore an exceedingly interesting tool concept for flat component surfaces.

The benefits

- Lower costs:

Great finishing performance and rapid machining - Lower tool costs:

Low wear because a longer section of the cutting edge is engaged - High component quality:

Low form tolerance of up to +/−5 μm on the cutter facilitates brilliant contour accuracy on the workpiece

- Application:

Exact and verified application parameters are available. The deliberately concise product portfolio covers a wide range of applications - FRAISA ToolExpert ArCut X:

for fast and easy provisioning of the cutting data - FRAISA ReTool®-Service:

Industrial tool reconditioning with performance guarantee

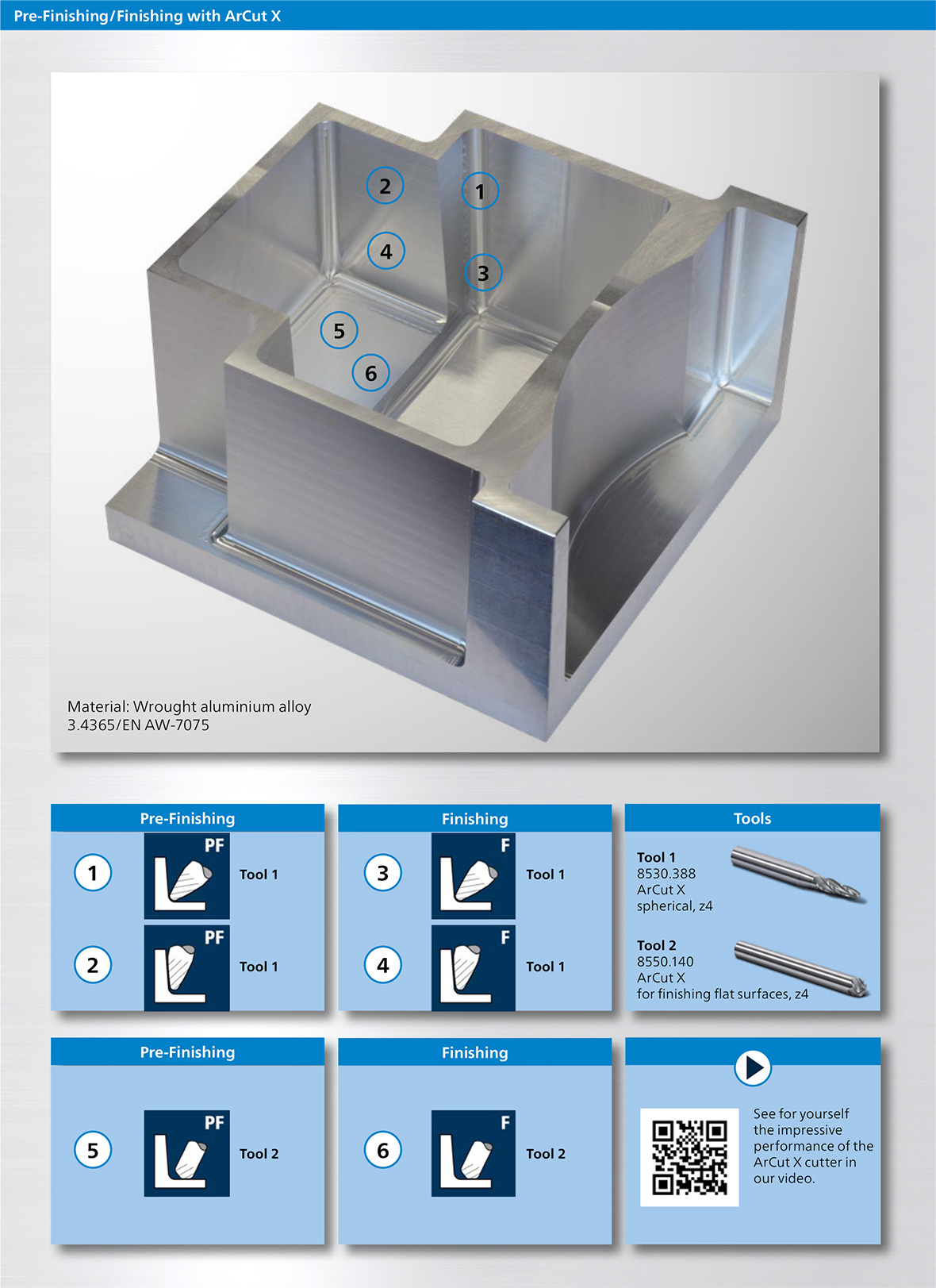

Application

With its ArCut X tool concept, FRAISA offers a range of conical end mills in various versions that covers a broad spectrum of finishing processes. In combination with the respective tool characteristics, the technologies facilitate a wide range of applications with a variety of materials.

Applicationvideos

The FRAISA ToolExpert cutting data calculator makes ArCut X even more attractive

Finishing in record time

Use of ArCut X demands a powerful CAM solution that fully exploits the potential of their geometry. Most leading CAM providers have now developed service packages that fully exploit the advantages of conical circular arc milling cutters and are easy to program.

The large radii at the curved cutting edge enable flat surfaces with big step-overs to be cut with excellent surface qualities. The large radii at the curved cutting edge enable flat surfaces with greater step-over distances to be cut and huge time savings of up to 90%!

Nutzen:

- Short production times:

time savings of up to 90% - Longer tool life

- Optimum surfaces

- Top productivity

- Wide range of applications:

Mould & Die making, aerospace, tyre moulds, turbine blades and impellers

ArCut X spherical and spherical, micro for finishing of steep slopes and radius areas

ArCut X toric and toric, integral for roughing of corners and finishing of steep areas

ArCut X spherical and toric for finishing of flat surfaces