hyperMILL® from OPEN MIND

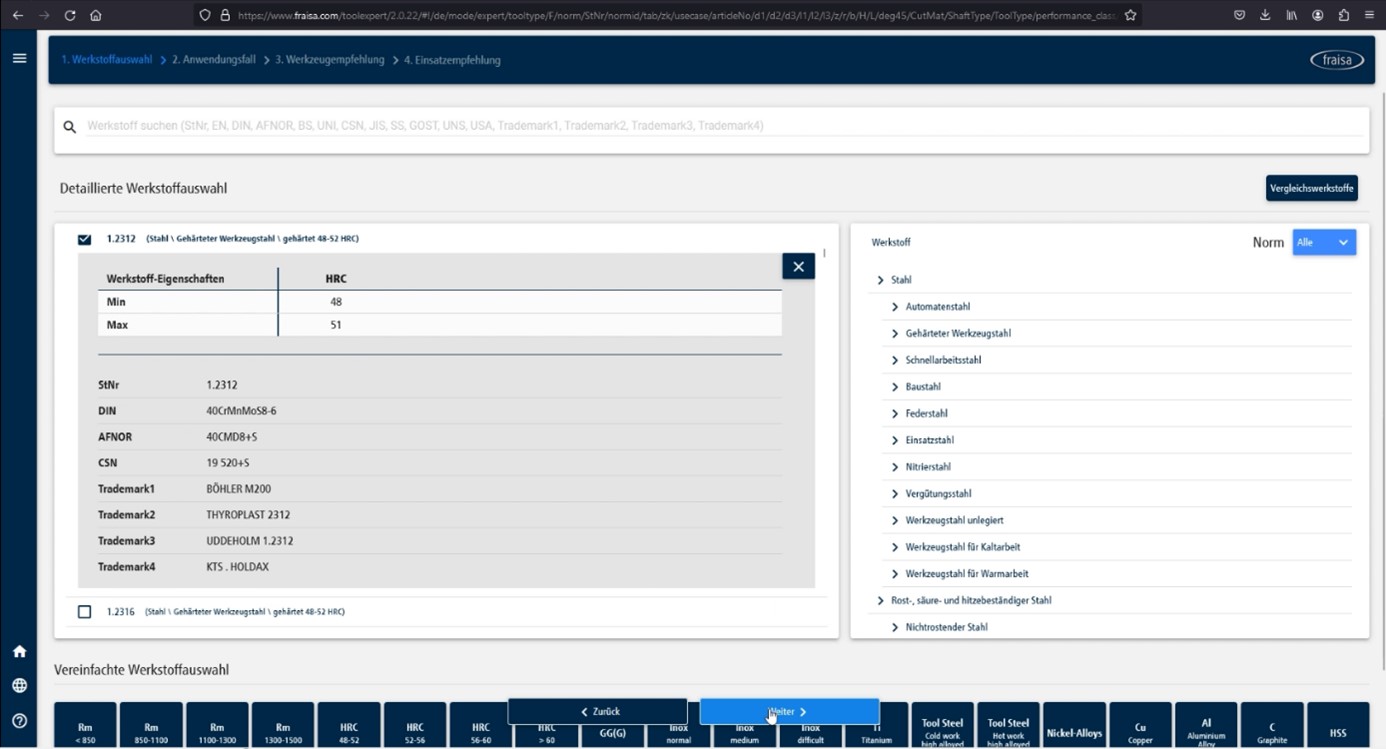

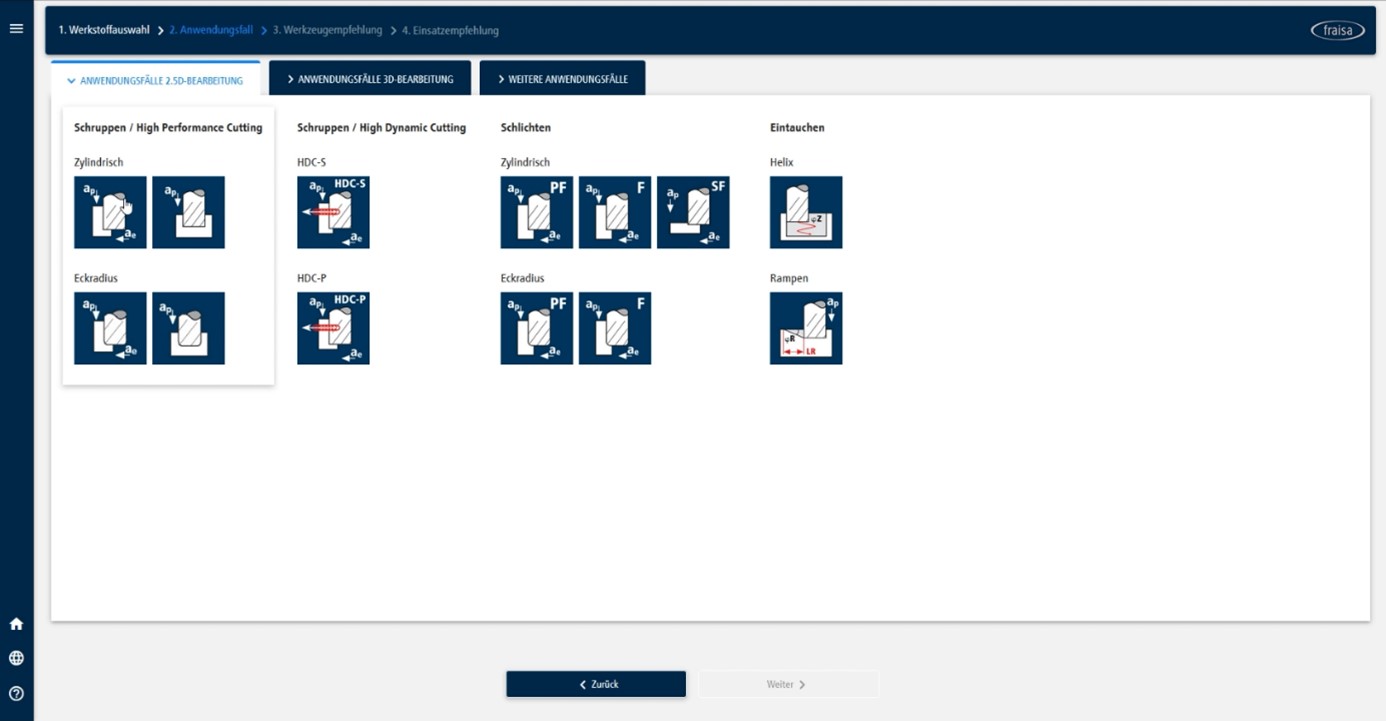

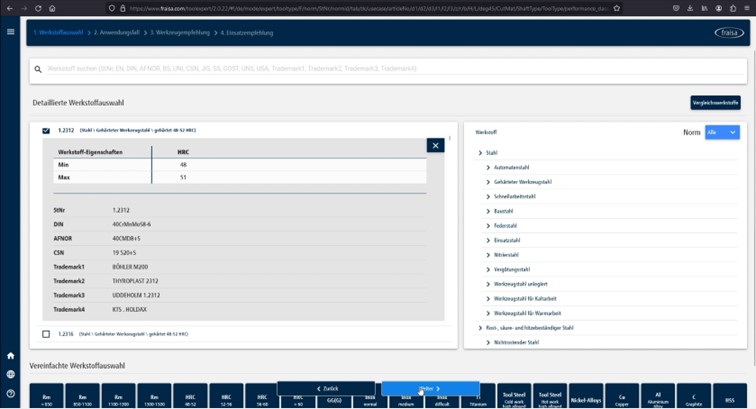

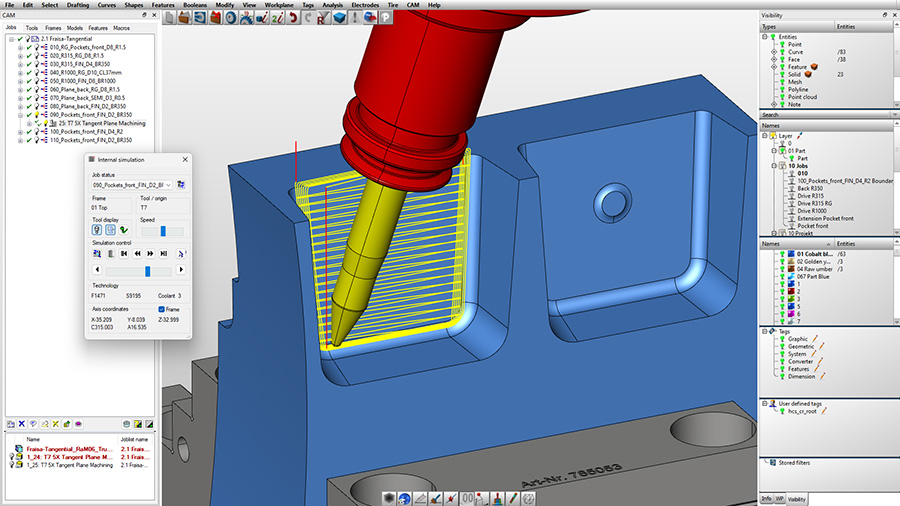

OPEN MIND develops CAD/CAM solutions for machine- and controller-independent NC programming. The powerful hyperMILL® CAD/CAM software enables precise programming of 2.5D, 3D, 5-axis milling and turning tasks. OPEN MIND was immediately impressed by the quality of the FRAISA cutting data and planned the implementation of an interface - the foundation stone was laid for one of the first partnerships in the development of online cutting data technologies.

Functions & features

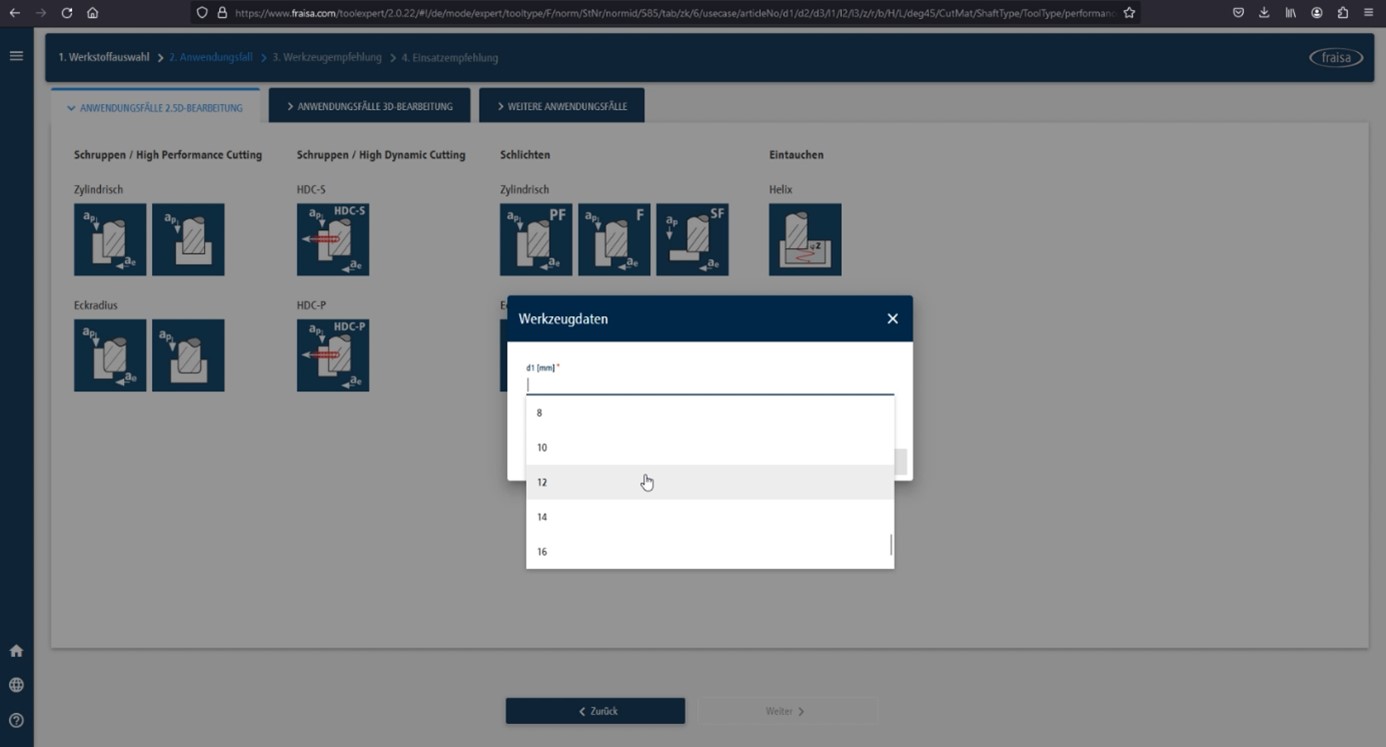

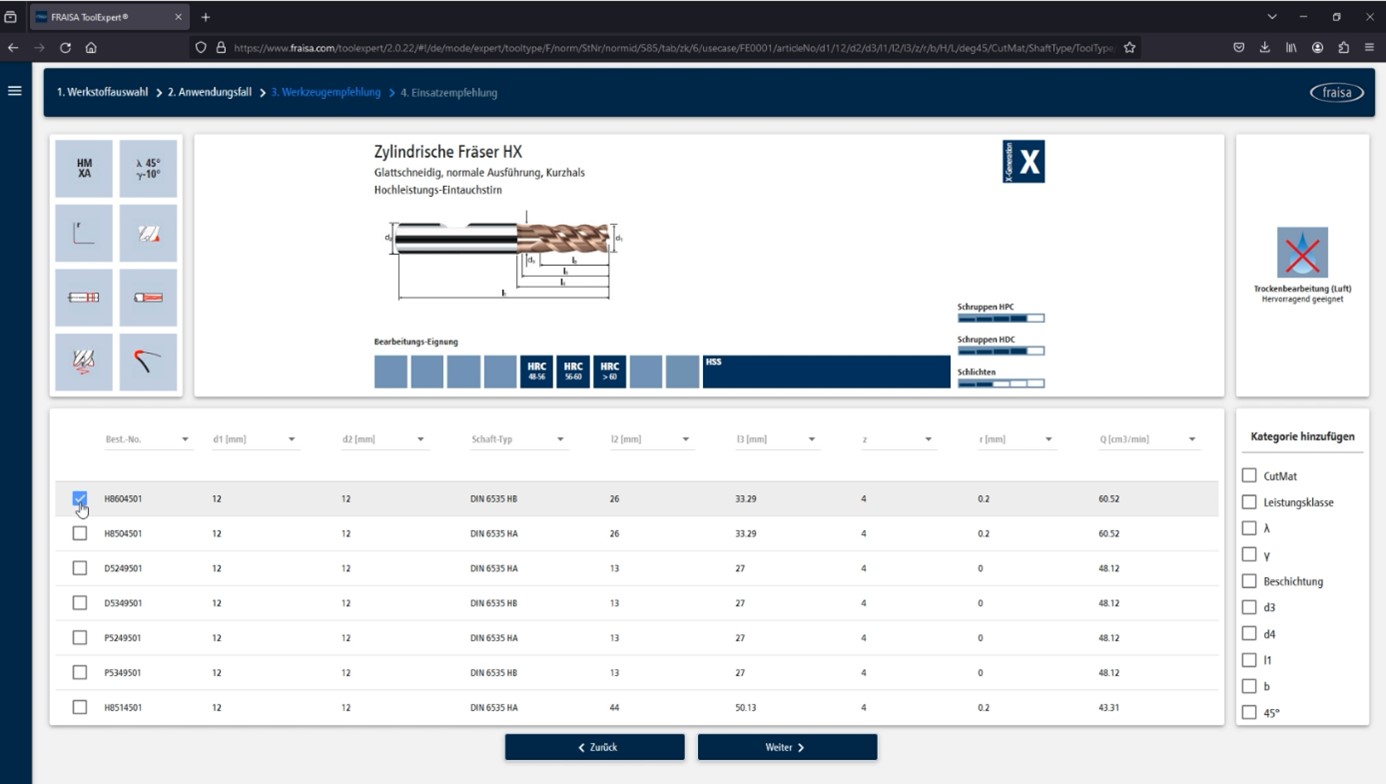

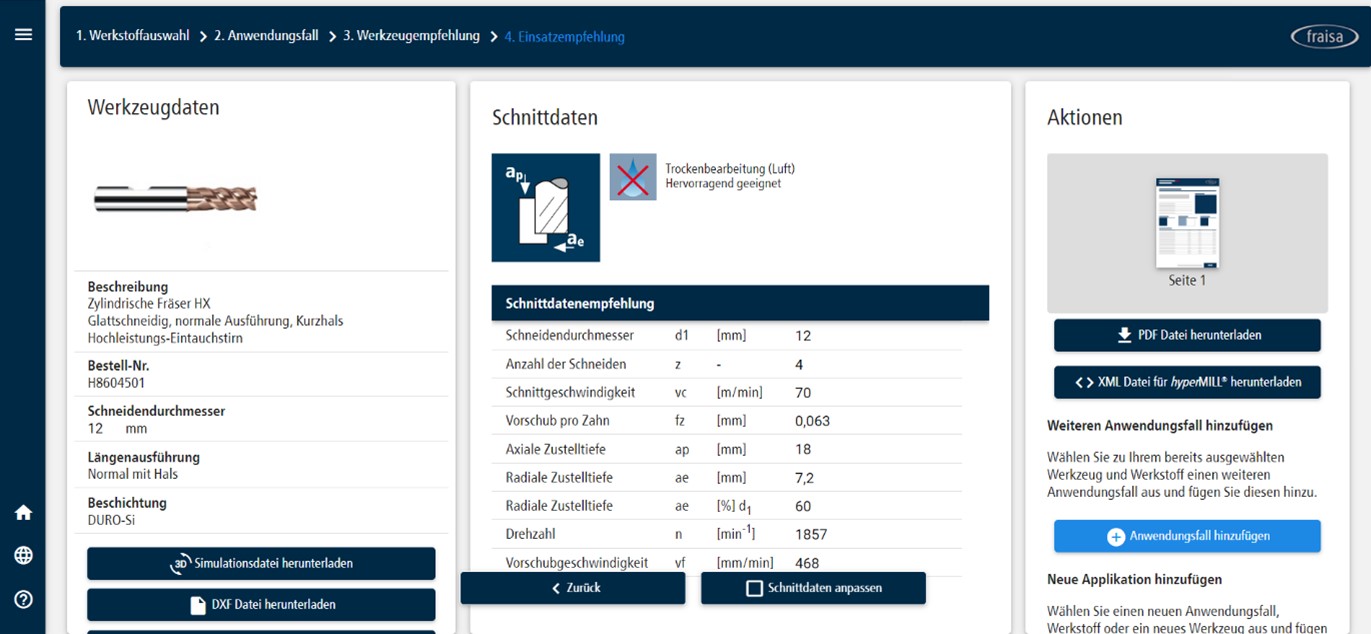

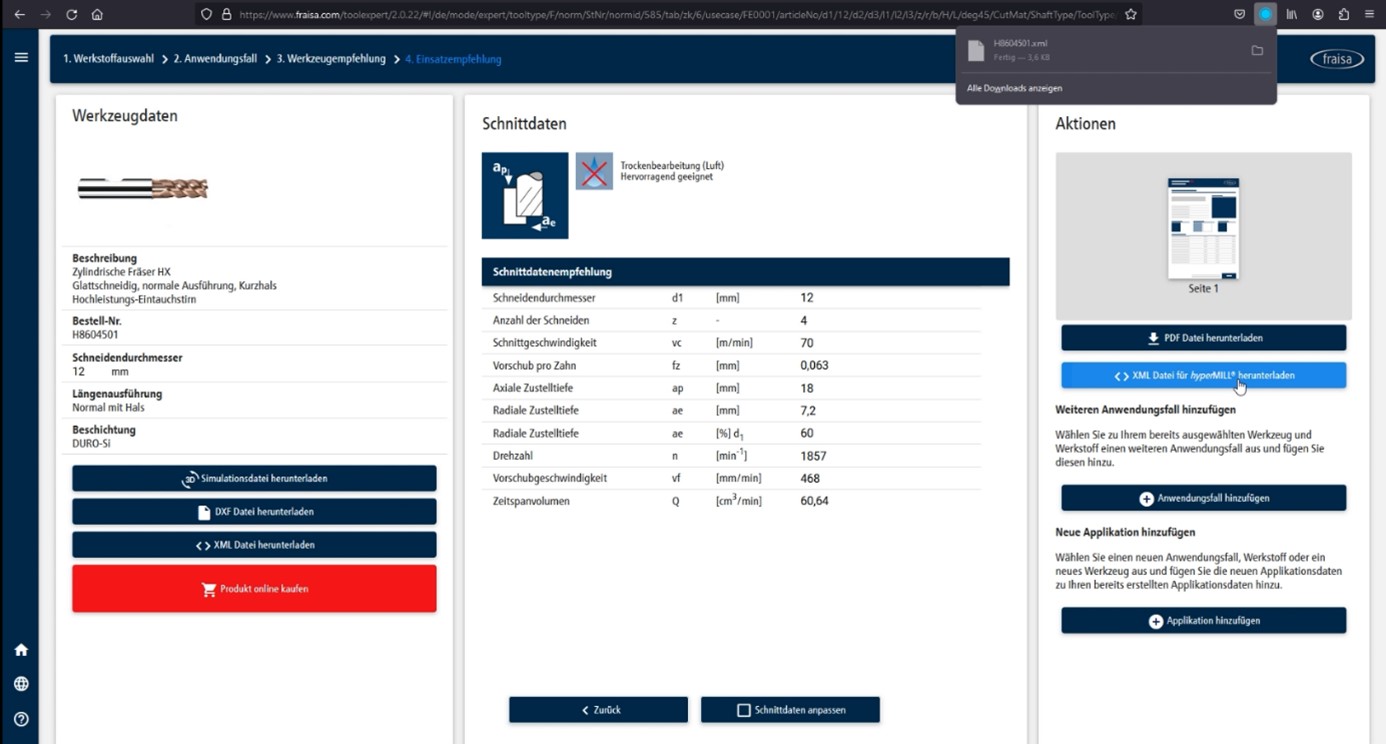

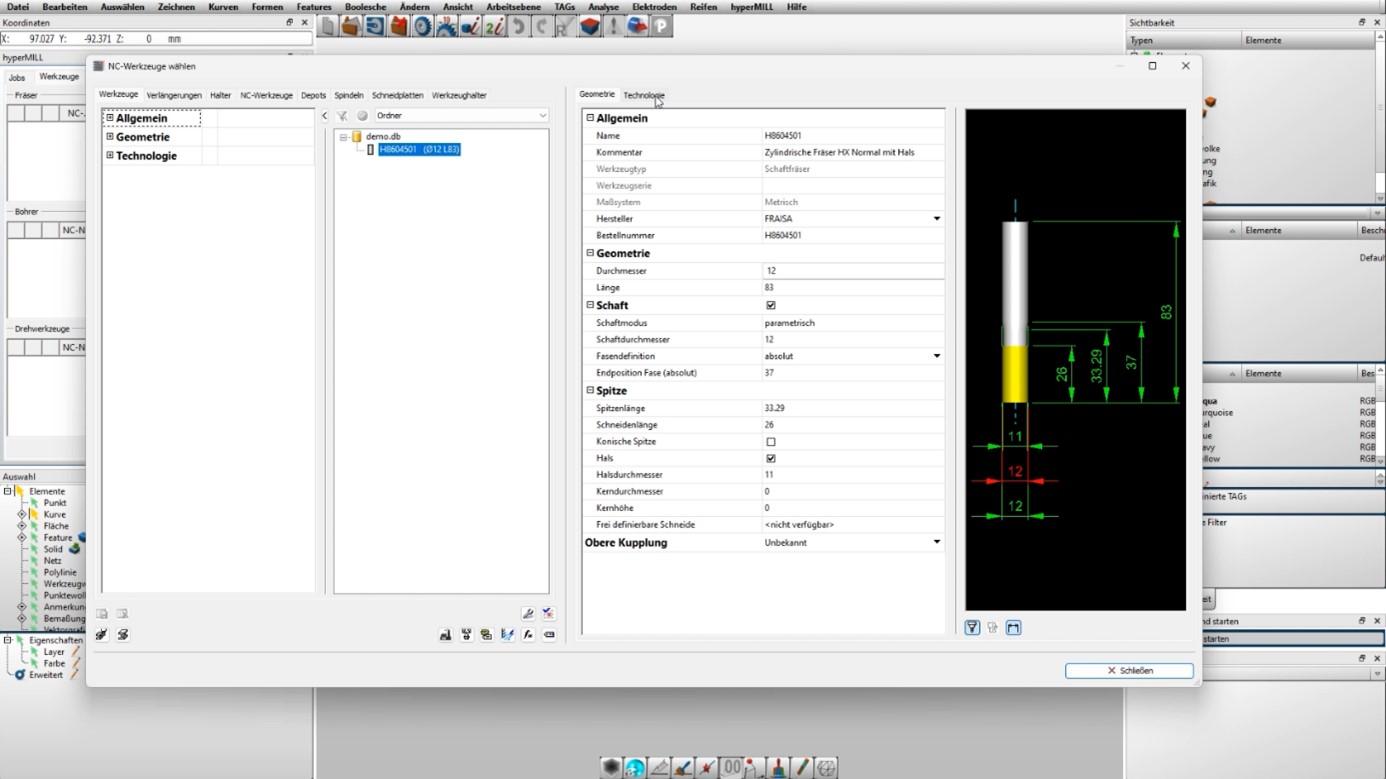

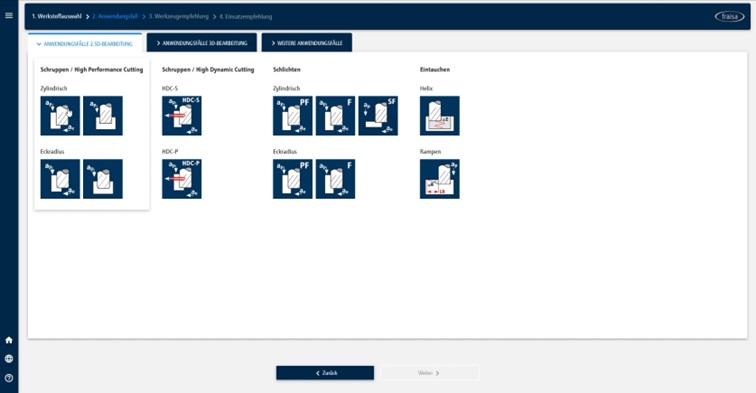

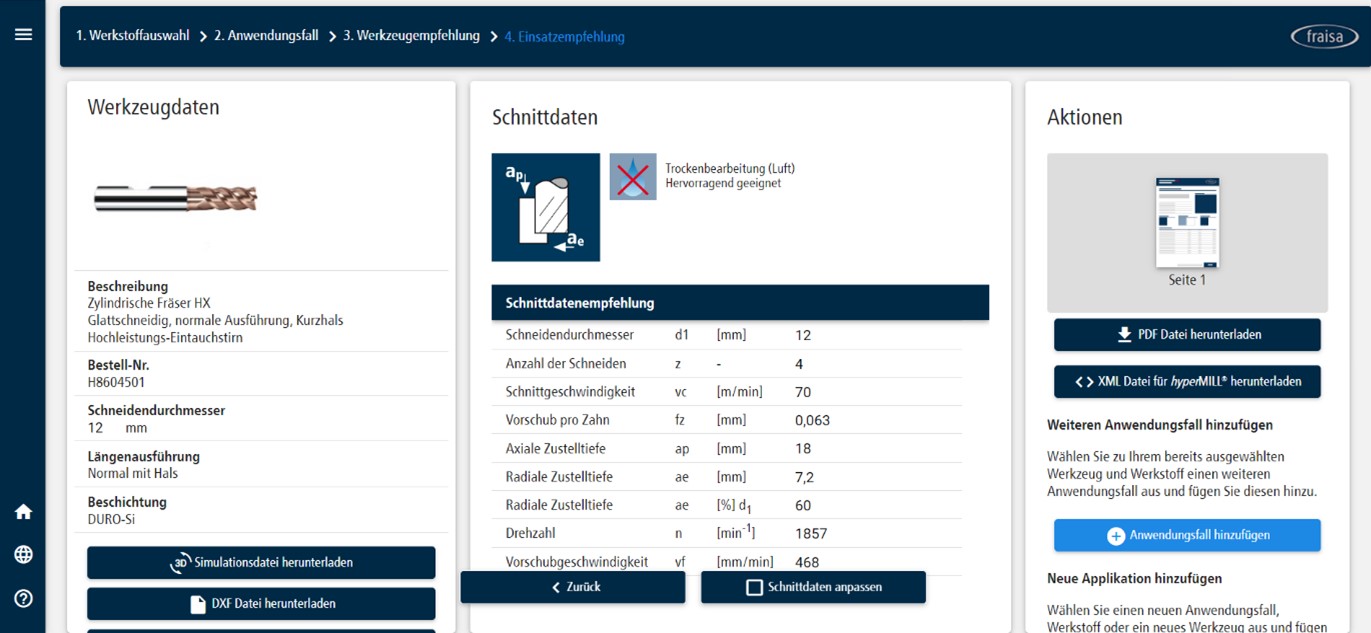

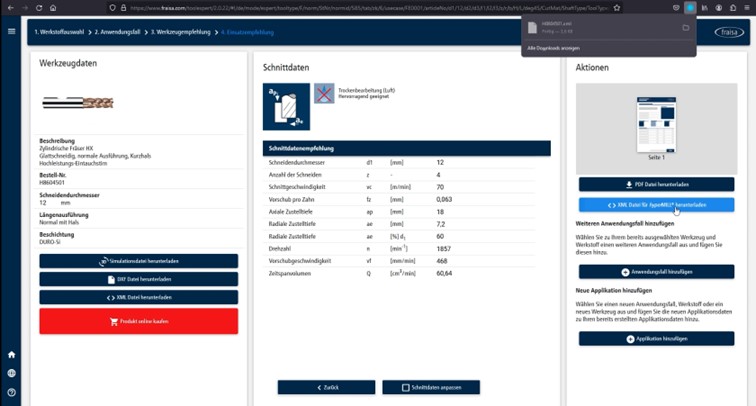

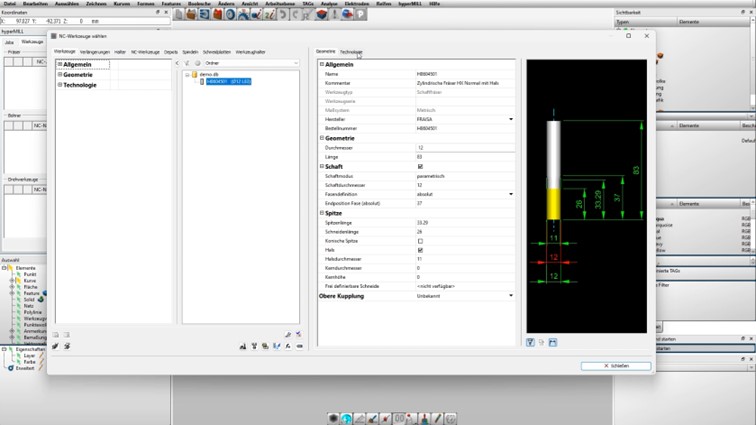

By integrating an XML interface, the process-reliable geometry and cutting data determined in FRAISA ToolExpert® can be imported directly and quickly into the hyperMILL® CAD/CAM software.

Manual input is no longer necessary, which significantly simplifies and improves its use. By transferring the relevant data directly to hyperMILL®, the entire process is shorter, more efficient and less prone to errors.

The data set can be expanded at any time to include additional use cases for the selected tool or other applications or tools. This means that even more extensive machining operations can be integrated into the CAD/CAM system with just one data set, saving time.

Material data from the FRAISA material database can be synchronized with the customer's existing material database. Parameterized "digital twins" are used to simulate component machining (collision control and material removal).

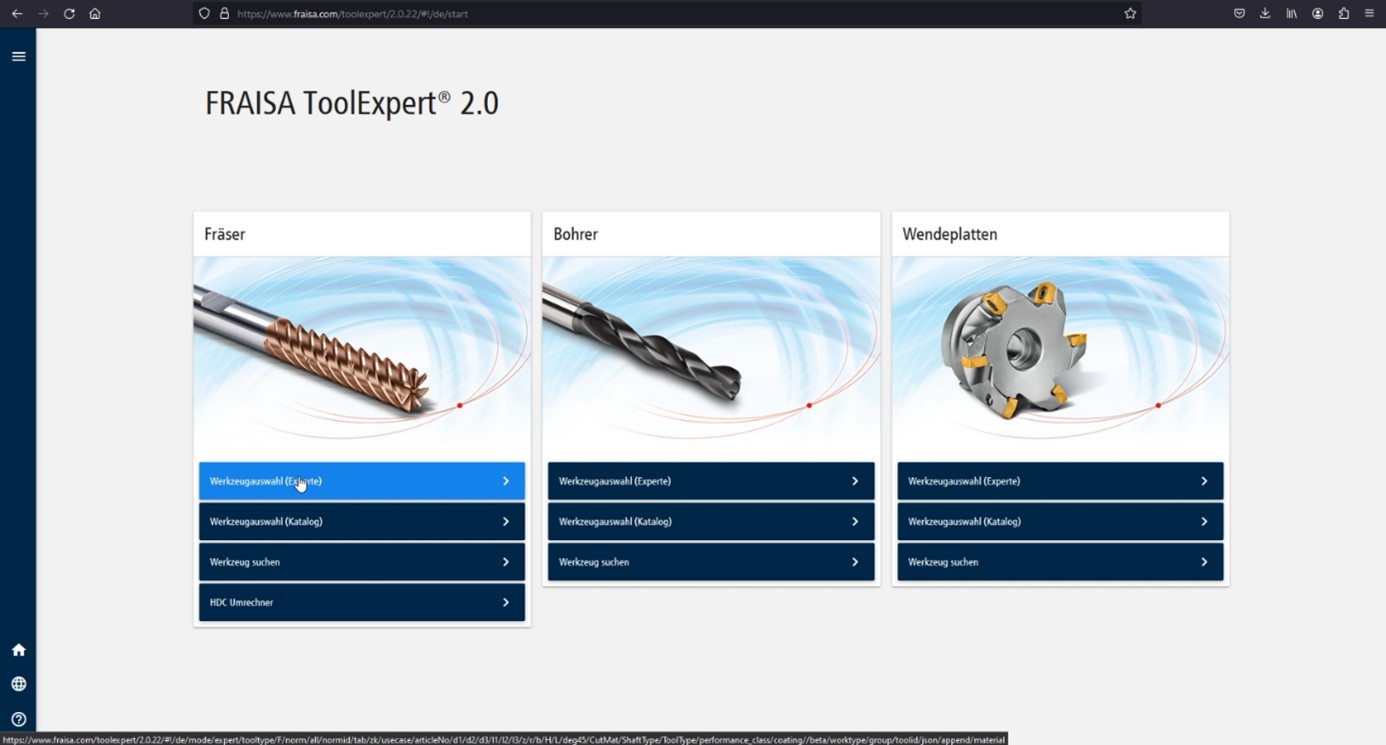

The application data is available for all FRAISA milling and drilling tools.

Advantages

- Optimization of production processes

- Direct import, no more manual input

- High process reliability

- Simplified and efficient use

- Reduced susceptibility to errors

- Significant time savings

- Import of complete data

- Simplified database maintenance

- Also for FRAISA ToolExpert® ArCut X