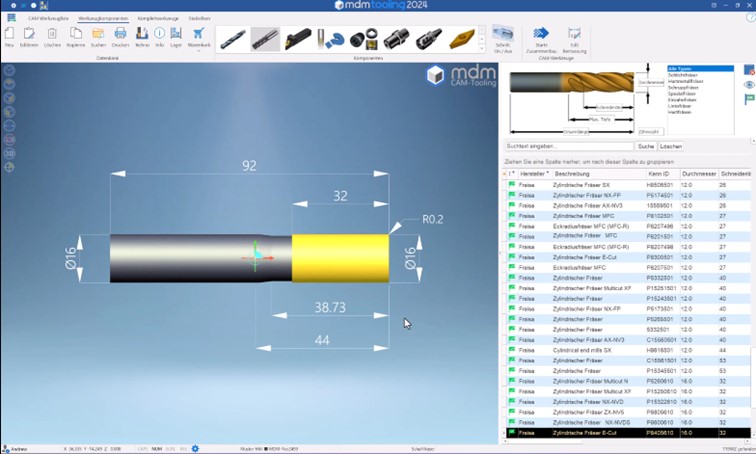

mdm

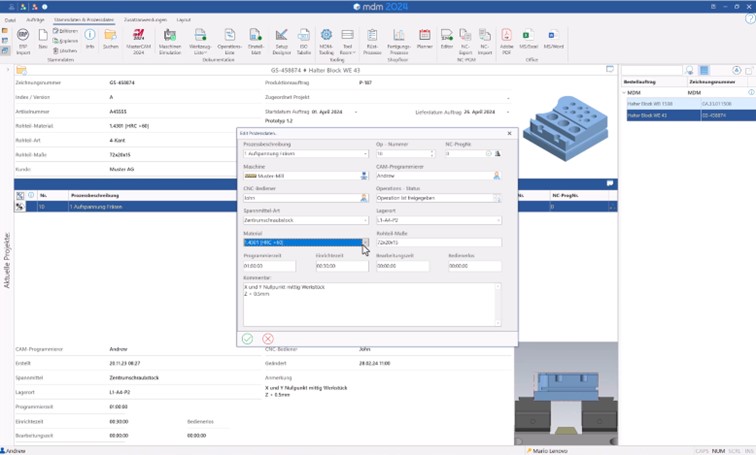

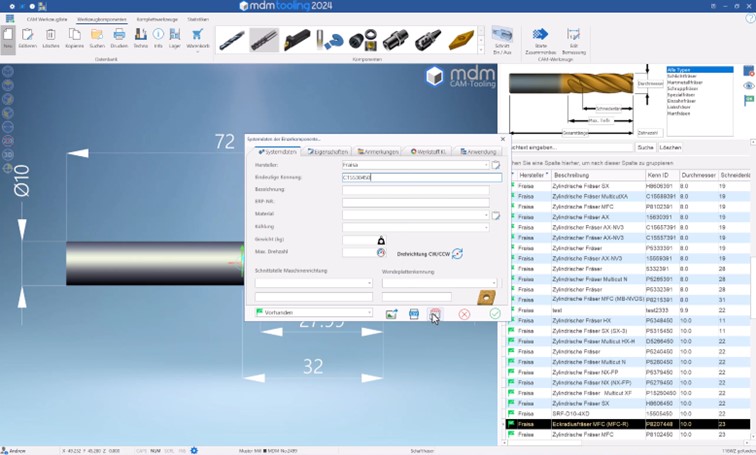

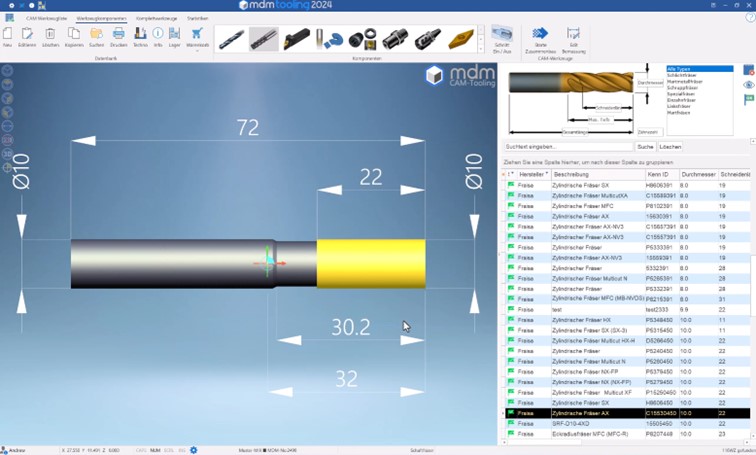

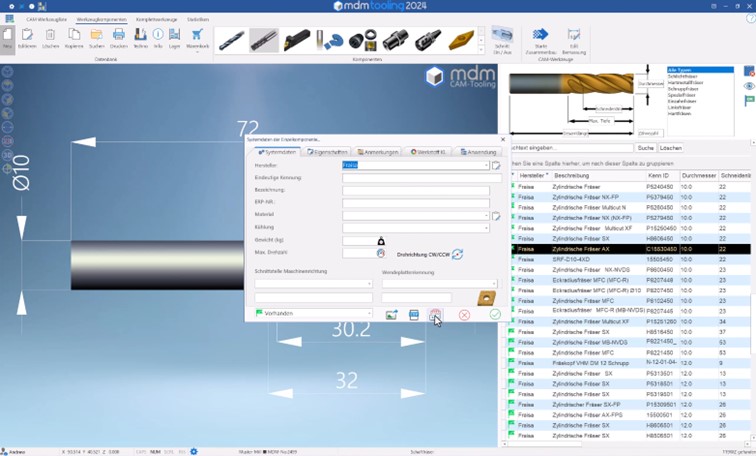

With mdm, all documents relevant to production can be archived efficiently and intelligently. All information is stored in a central SQL database and is available via a network at any location. With the interface connection to a Tool Data Management system, FRAISA has achieved a successful premiere in cooperation with the Liechtenstein-based company mdm software group AG.

Functions & Features

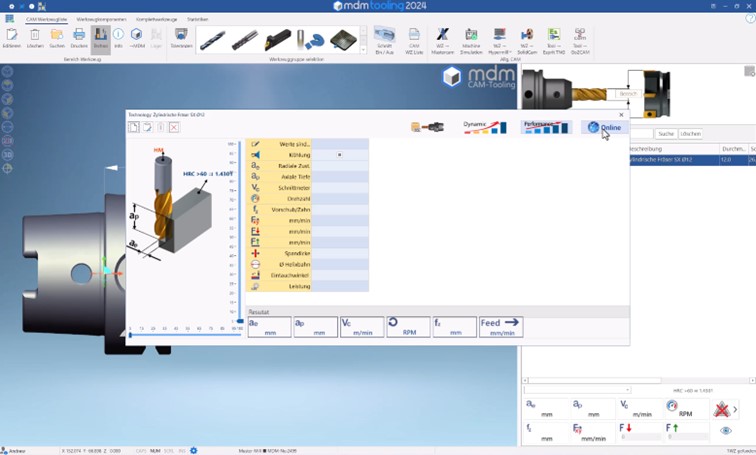

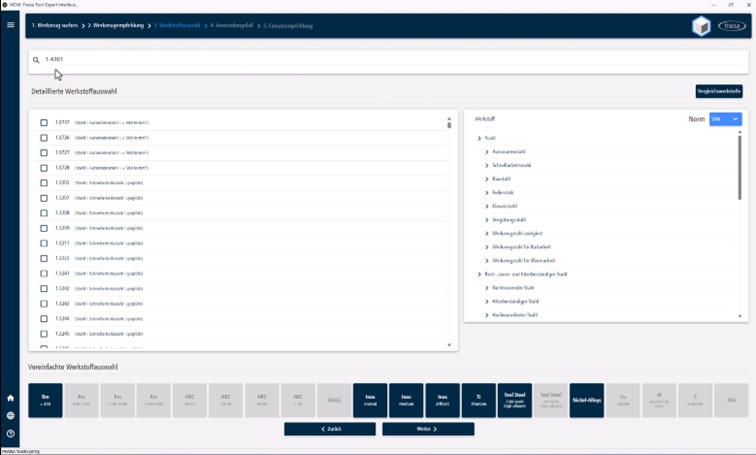

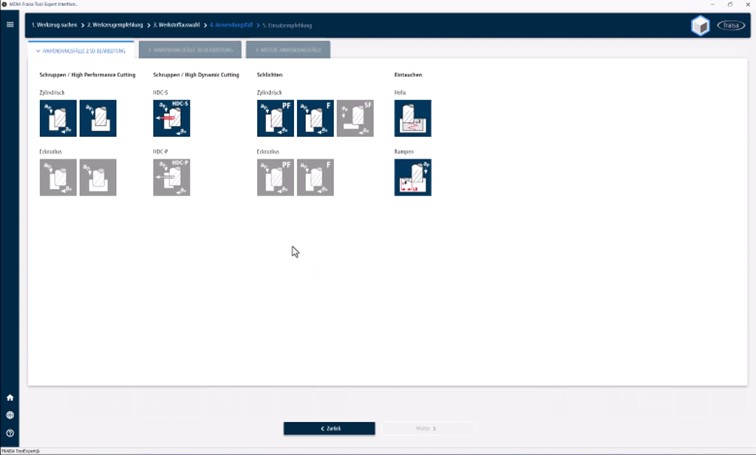

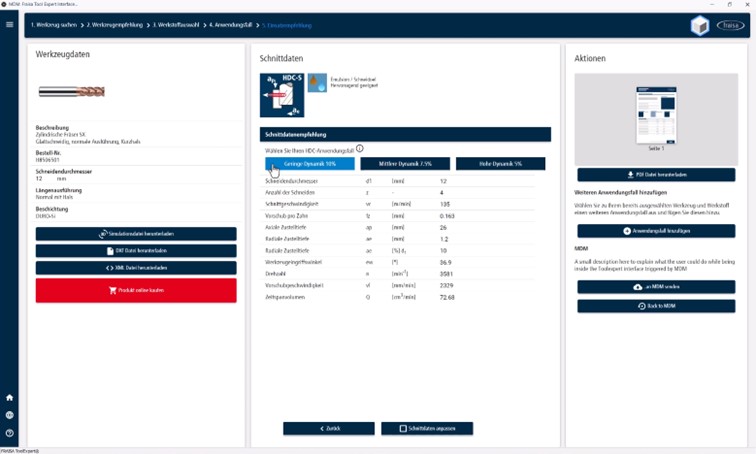

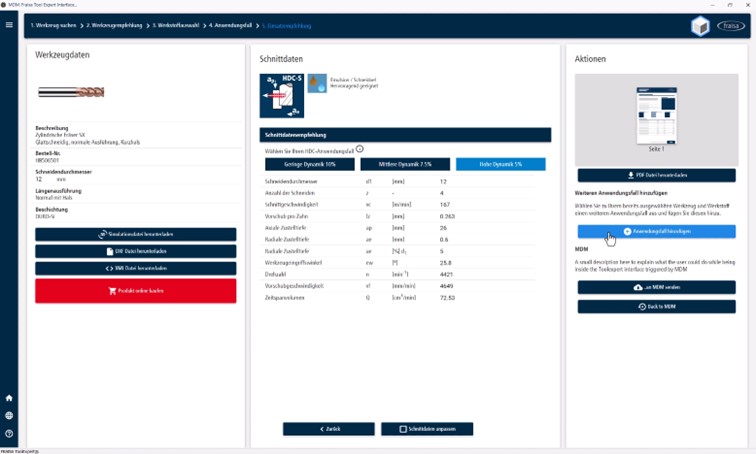

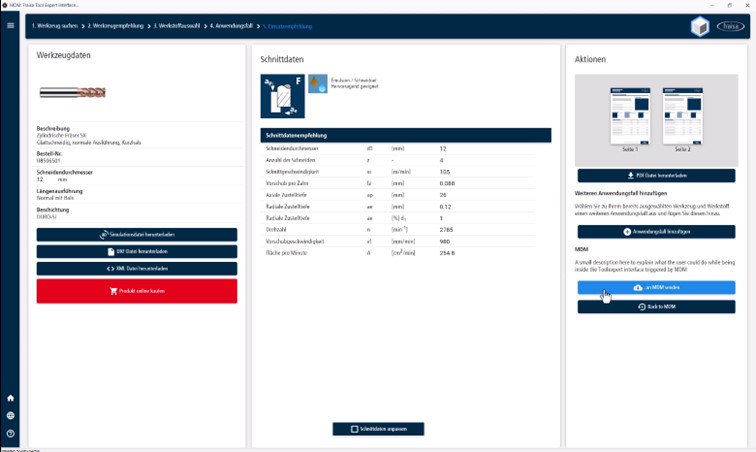

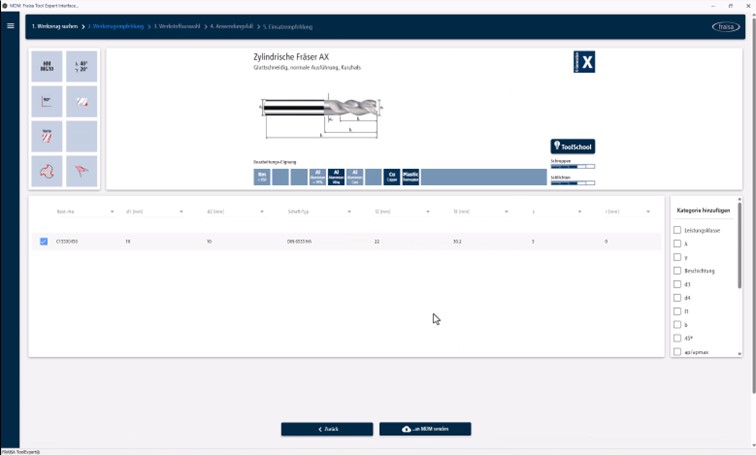

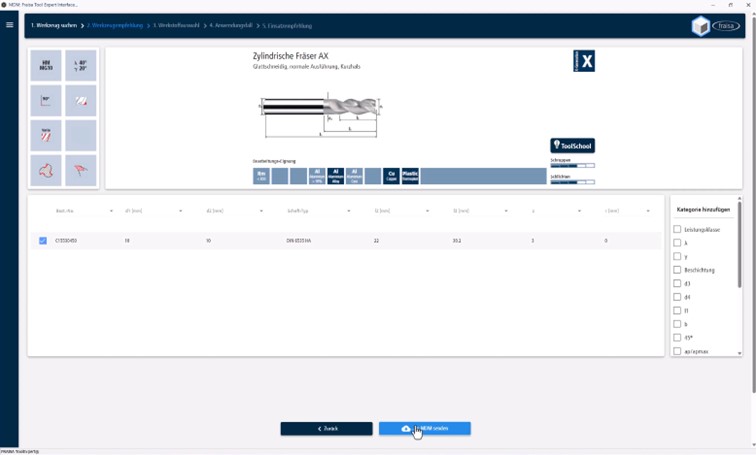

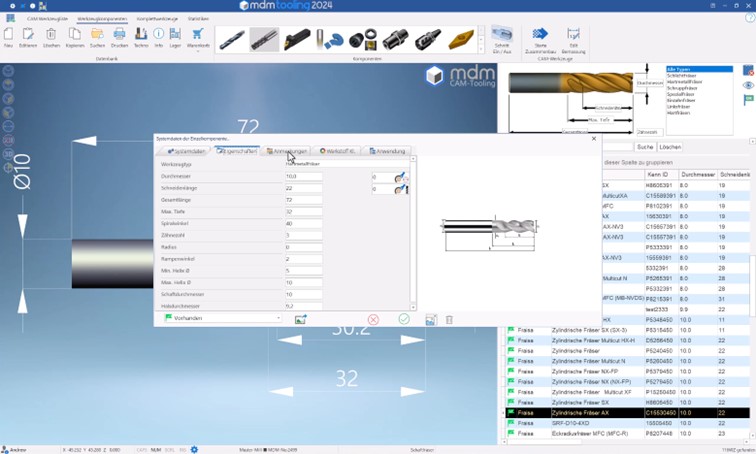

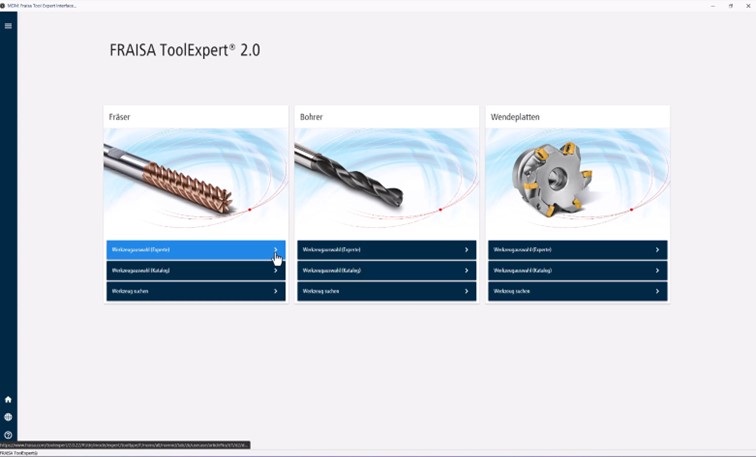

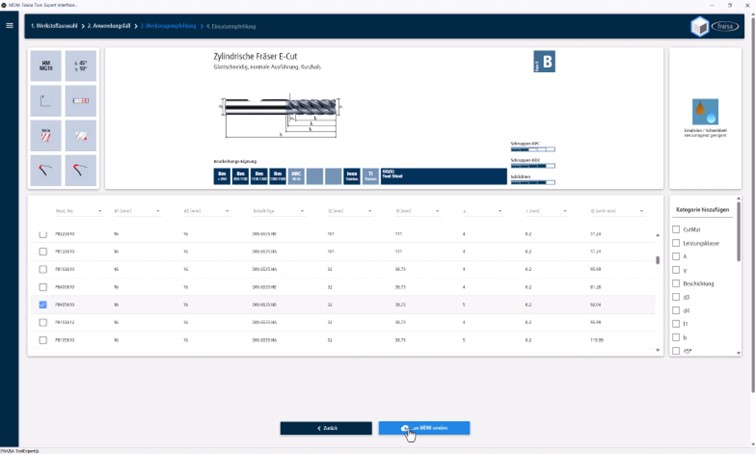

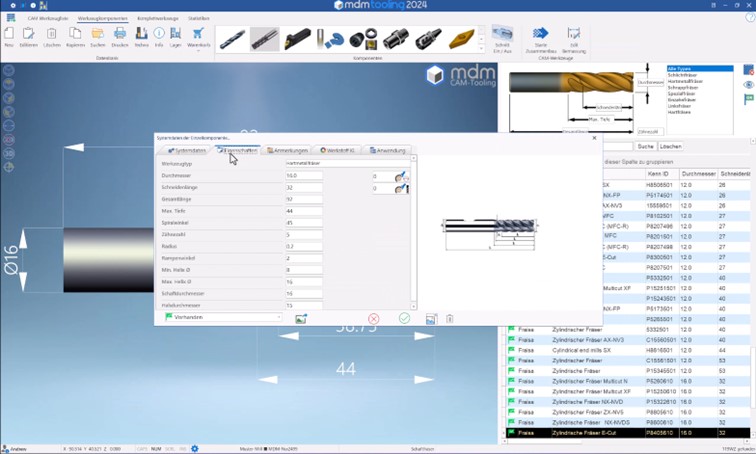

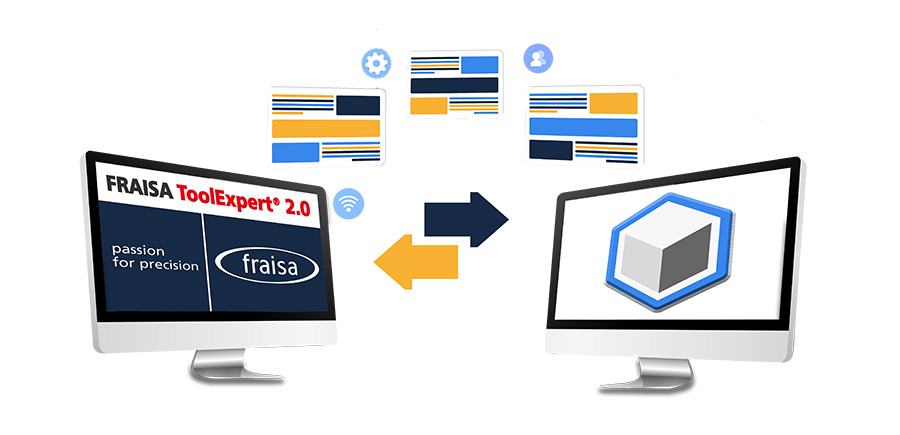

Automated data integration between FRAISA ToolExpert® and mdm to optimize production processes: Two different workflows are available to choose from to import the checked geometry and cutting data quickly and easily via a JSON interface. Additional use cases can be added at any time for more extensive processing.

Error-prone manual input is no longer necessary - the CAM user therefore benefits from a shortened and more efficient work process as well as a high level of process reliability.

The application data is available for all milling and drilling tools and inserts from FRAISA.

Advantages

- Optimization of production processes

- Direct import, no more manual input

- High process reliability

- Simplified and efficient use

- Reduced susceptibility to errors

- Significant time savings

- Addition of further use cases