Favora® tool concept:

End mills with a universal range of applications

High performance and tool life

Universal range of applications

Outstanding price - performance ratio

Sustainability thanks to the FRAISA ReTool®Services

Consistent l/d ratios

Application data in the FRAISA ToolExpert®

High-performance technologies for the Favora® class

The new Favora® from FRAISA stands out thanks to its universality, high performance and tool life - making them unbeatably efficient. The milling concept, for diameters between 1 mm to 20 mm, covers a wide range of applications and components and is also suitable for High Dynamic Cutting strategies, HDC-S and HDC-P (trochoidal milling).

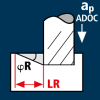

FRAISA is also happy to announce and addition to the Favora® tool family: The existing product range with the normal and medium length version is being expanded to include a tool variant with a corner radius and the extra-long 5.2xd version. This results in an even wider range of applications, especially in softer steels and stainless steels.

Applications:

Cylindrical end mill and corner radius end mill, normal version

The symmetrical component has been milled with both Favora® tools.

All applications mentioned below are covered by both tools.

1

1

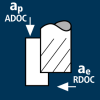

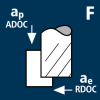

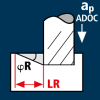

Roughing - High Performance Cutting (HPC) laterally

2

2

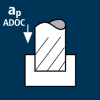

Roughing – High Performance Cutting (HPC) slots

3

3

Penetration helical interpolation

4

4

Penetration ramping

5

5

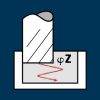

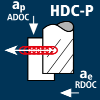

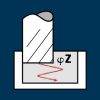

Roughing - trochoidal milling /High Dynamic Cutting – Performance (HDC-P)

6

6

Roughing- trochoidal milling /High Dynamic Cutting – Speed (HDC-S)

7

7

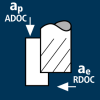

Pre-finishing

8

8

Finishing

Cylindrical end mill, normal version

new!

new!

Corner radius end mill, normal version

Applications:

Cylindrical end mill, medium length and extra-long version 5.2xd

This component was produced with the medium-length and extra-long 5.2xd Favora® tool.

The possible applications of both tools can be found below.

1

1

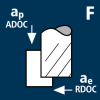

Roughing - High Performance Cutting (HPC) laterally

2

2

Roughing – High Performance Cutting (HPC) slots

3

3

Penetration ramping

4

4

Penetration helical interpolation

5

5

Roughing - trochoidal milling /High Dynamic Cutting – Speed (HDC-S)

6

6

Pre-finishing

7

7

Finishing

Cylindrical end mill, medium length version

new!

new!

Cylindrical end mill, extra-long version 5.2xd

Application videos - Our Favora® tools in use

All data for the application videos below can be found in our FRAISA ToolExpert®.

Application 1

Application 2

High-precision cutting data

The FRAISA ToolExpert® offers an optimal base for reliable and efficient use of the new Favora® tools:

Optimal operating parameters can be found quickly and reliably

Perfectly coordinated tool- and material-specific cutting data can be used directly

Provides valuable support for complex application technologies

You can also find the relevant application and cutting data in our catalog.

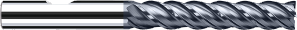

Favora® – Geometry & function

Thanks to new grinding strategies and improved manufacturing processes, these high-performance technologies can now also be utilized for Favora® tools. When using this high-performance all-rounder, the user not only benefits from high quality and reduced logistics costs, but also from high efficiency and a low CO2 footprint.

The tools of the Favora® product range work excellently in their broad application range due to their geometrical design. Even heavy cuts in the roughing process are no problem for the high-performance universal end mill thanks to its stable core.

The positive cutting edge and variable helix guarantee good surface qualities in finishing operations. The partially polished blade enables the absorption of high cutting forces. When selecting the substrate and the coating, the focus was on a long tool life and a perfectly predictable application behavior.

Partially polished blade

Chip breaker system (P46320)

Corner radius

45° or 43° helix angle,

6° cutting angle

Variable helix

Smooth transitions (P46307)

Special edge conditioning