NX technology: For surface qualities below Ra 0.1 μm

FRAISA’s NX face-finishing cutter is the latest innovation in finishing. The new milling cutter mills plane surfaces that are both visually and measurably of top quality. The secret lies in its axially and radially offset finish-cutting edge. Thanks to this offset, the finish-cutting edge cuts a precisely defined cross-section of chip measuring just a few hundredths of a millimeter. The finish-cutting edge is designed exactly for this chip cross-section and produces brilliant surface qualities.

The NX face-finishing cutter enables you to machine parts to surface roughness qualities of Ra < 0.1 μm. For many parts, this eliminates any need for a further process step as grinding is no longer necessary. The great advantage: The part can be finished in the same process on the same machine, saving considerable cost and time.

The NX face-finishing cutter has been designed so that even small, unavoidable radial deflections of the tool do not affect the machining result.

Since a perfect transition is often desired between the base and the wall, the NX face-finishing cutter also has short cutting edges at its circumference, so that step-free transitions can be created.

If you value outstanding surface roughness qualities or want to embellish visible components, you will be amazed by what FRAISA’s new NX technology has to offer.

The advantages

- Top surface quality Visually and measurably much better surface roughness quality than with conventional tools

- Easy to use Tools can be used for normal 2D facing or for pocket milling

- Ideal life cycle with FRAISA ToolCare® tool management, FRAISA ReTool® tool reconditioning, and FRAISA ReToolBlue tool recycling

- Reduced process costs Times for finishing processes such as grinding or polishing are cut significantly

- FRAISA ToolExpert® 2.0 cutting data calculator for quick and easy provision of cutting data

The technologies of the NX face-finishing

New feature combines with tried and trusted: The new technology of cutters with a face-finishing cutting edge is characterized by the fact that an additional cutting edge is ground between the existing ones.

Thanks to the high-precision shank, the smooth transitions and fine balancing, the tool functions superbly.

NX face-finishing cutter for the very best surface quality – visually and measurably

Choosing the right strategy

If you want to obtain surface finishes of the highest quality, it is crucial you choose the right strategy. The following requirements should be taken into account:

Fluid movements, the tool should never stand still

Fluid movements, the tool should never stand still

No sharp corners if possible

No sharp corners if possible

Reduce the feed rate in corners

Reduce the feed rate in corners

Application tips for tools with a face-finishing cutting edge

Pocket machining

The right workflow is important to minimize the amount of rest material in the corners of a pocket or step. Our product developers therefore recommend prefinishing after roughing and then finishing the base first before the wall.

The NX face-finishing cutter will mill the base and the wall together. Machining of the base is then complete. The wall still has a minimal allowance and is then finished with a finishing tool.

Measuring the tools

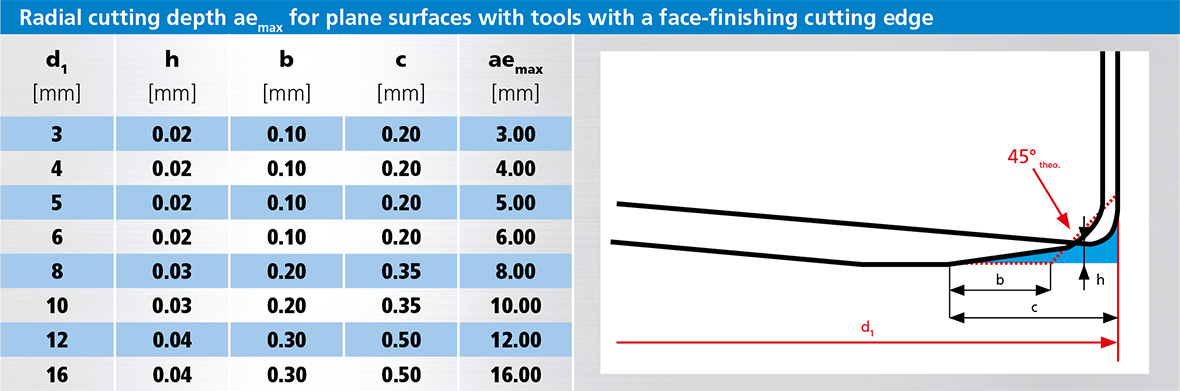

When measuring the tool on the machine using a laser, it is very important to specify the correct tool offset. To measure the diameter, a length offset Loff of at least h must be specified – FRAISA recommends an Loff of 1–2 mm.

Machining precision also requires taking a close look at the radius offset. Why? The lowest point of the tool is not at the cutting-edge corner, but a few tenths of a millimeter towards the center. A radial offset Roff of c must therefore be specified in the tool table.

FRAISA performance guarantee through industrial reconditioning

FRAISA ReTool® guarantees 100 % of the machining performance and service life of a new tool. Industrial reconditioning is already being considered during tool development. Our automated production processes ensure maximum performance stability.

Cost savings thanks to FRAISA performance guarantee

Thanks to the FRAISA performance guarantee, you benefit from the reliable 100 % performance of the reconditioned tools. Your machines can produce at an output of 100 % – with new tools as well as after the first, second or third reconditioning.