The MicroX success story in four dimensions

We are presenting our attractive MicroX range in a greatly expanded form – a success story in four dimensions!

This product range, now expanded to almost 500 items in diameters ranging from 0.1 to 3.0 mm, sets new benchmarks with respect to performance, completeness and simple and quick tool selection, opening up new options for high-precision micro-milling.

With the four perfectly coordinated dimensions “Range,” “Technology,” “Service,” and “Application,” MicroX offers a clever solution for maximum customer value in finishing and superfinishing.

Technology

- Tolerances for balls +/–0.005 mm and corner radii 0/+0.01 mm

- 6 mm precision shanks with h5 tolerance for best component qualities

- Extensive options: Corner radii with r 0.05 / 0.1 / 0.2 / 0.3 / 0.5 mm

- Optimized suitability for 3-axis, 3+2-axis and 5-axis milling

Range

- First-rate selection: 478 different micro cutters from 1xd to 20xd, available as ball nose end, corner-radius, and cylindrical mills, with 2 or 4 teeth

- Smart range structure for simple and quick tool selection in the 0.1 to 3.0 mm dia. range

- Outstanding selection options for 1xd to 6xd high-precision milling

Service

- ToolCare 2.1: management, procurement, and information system for tools

- ConcepTool: custommade special tools

- ToolSchool: initial and continuous training

- FRAISA ReTool®: industrial tool reconditioning with performance guarantee

Application

- High availability and easy ordering with nextday delivery throughout Europe

- FRAISA ToolExpert: Accurate and reliable application data for every tool available online

- CAD data available on website

- Maximum efficiency for finishing and superfinishingin steels from 40 to 60 HRC

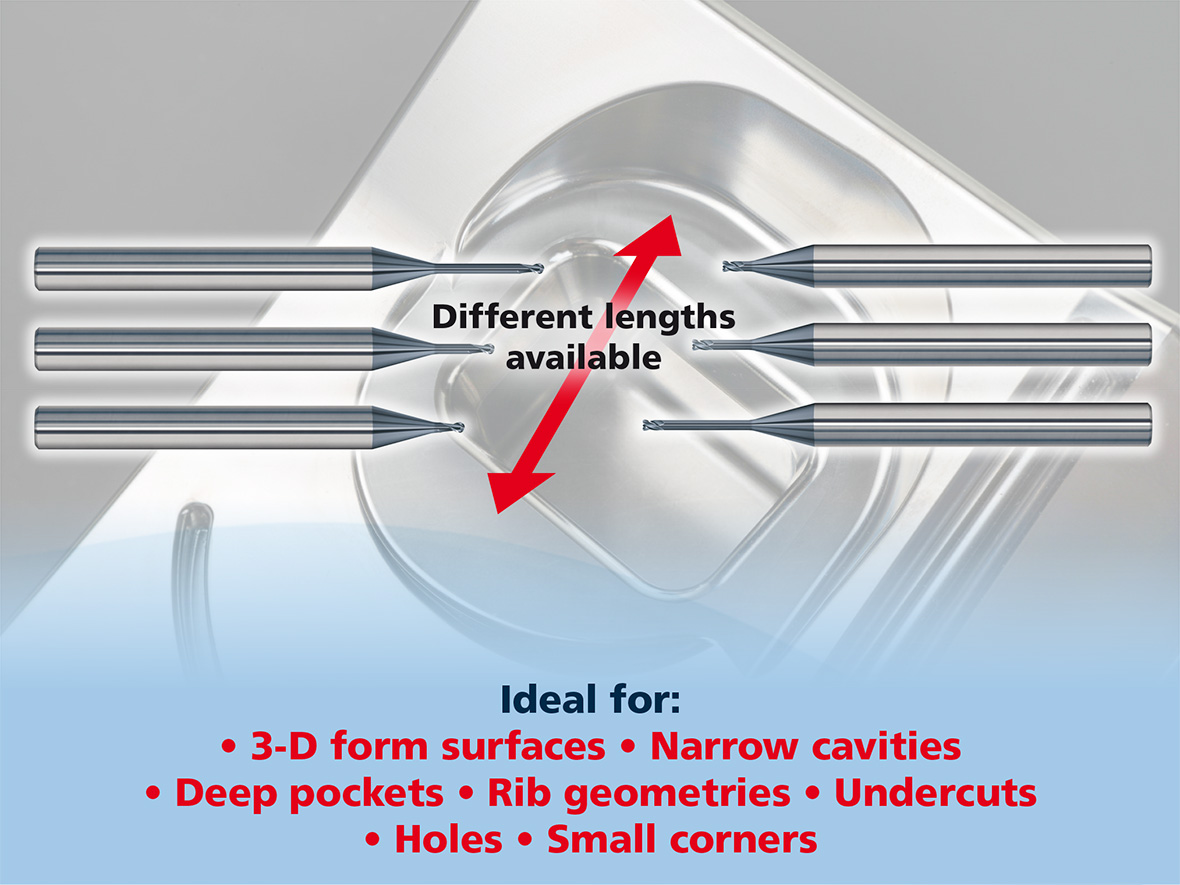

478 different micro cutters for first-rate tool selection

With MicroX, FRAISA offers an innovative tool solution for cost-effective production of complex geometric components.

Optimum surface qualities must be archieved and the machining of challenging geometries must also be guaranteed as the dimensional accuracy of the workpiece. The MicroX range, which has been expanded to almost 500 different items, offers an outstanding selection from which to choose

and ensures that the ideal tool variant is available within the length and diameter range (l/d) from 1xd to 20xd. Especially for high-precision milling between 1xd and 6xd, FRAISA has set new standards with over 270 items for maximum customer choice.

MicroX tools are ideally suited to machining steels in the strength range Rm = 850 N/mm2 to 60 HRC as well as stainless steels and titanium.

With its expanded range, MicroX now offers 478 different options. The following product pages give further details about the items available.

Maximum precision and efficiency in finishing and superfinishing

MicroX ball end mills have a radius tolerance of +/-0.005 mm.

In order to really achieve this high level of precision, a measuring method is required that can measure the entire cutting edge over 180°. The radius is measured at 5° intervals: from 0° to 180°.

This ensures a level of precision that is within tolerance across the entire ball. The shank ground to tolerance zone h5 also significantly reduces the concentricity error and further increases the precision of the component.

Conventional measuring methods, on the other hand, generally measure only from 10° to 80° and from 100° to 170° in order to exclude the difficult- to-grind transitions between the radius and curved cutting edge and the center errors.

When such tools are used on conventional 3-axis machines, steep tapers and even bottom surfaces cannot be finished with sufficient contour accuracy.

Maximum performance

Thanks to the perfect coordination of the technical elements of the tools – carbide substrate, hard coating, micro and macro geometry – as well as an optimized CAM milling

strategy, MicroX provides outstanding performance and component quality with maximum process reliability. Flank wear after 64 minutes milling is only 8 μm!

Cutting-edge technology for maximum productivity