Machining technology meets industry-specific know-how

Every industry makes specific demands on its manufacturing processes. FRAISA’s machining (in the sense of chip removal) technology offers solutions that are tailored perfectly to customer and current market requirements. We trust in the high quality of our products and in the certainty that we can offer great customer benefits achieved through industry-specific research and development work.

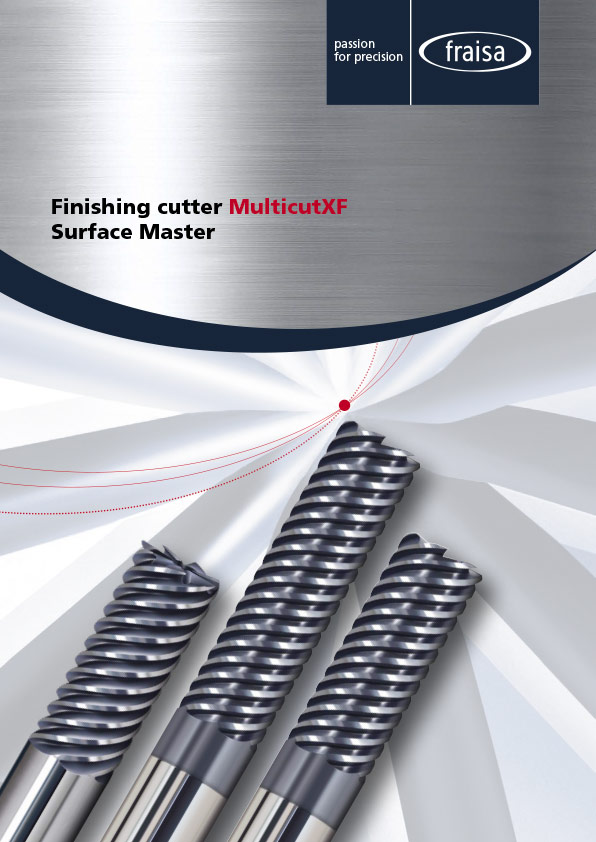

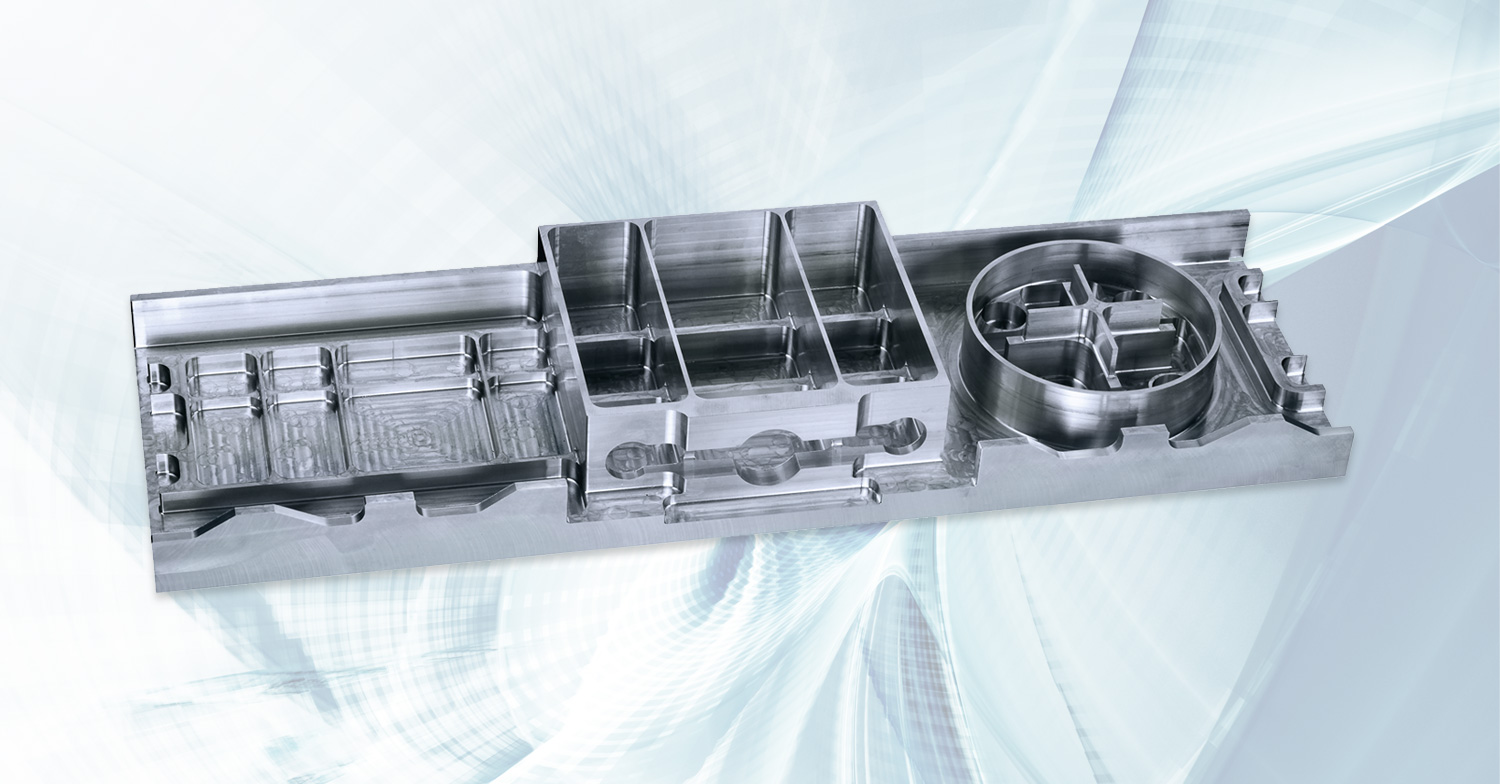

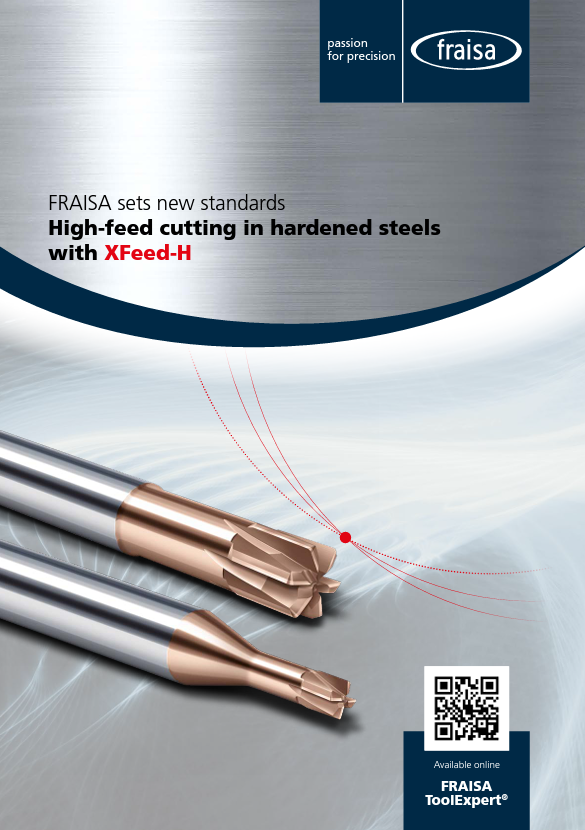

Toolmaking

With a production share of up to 50%, milling is one of the core technologies deployed in tool and mold making.

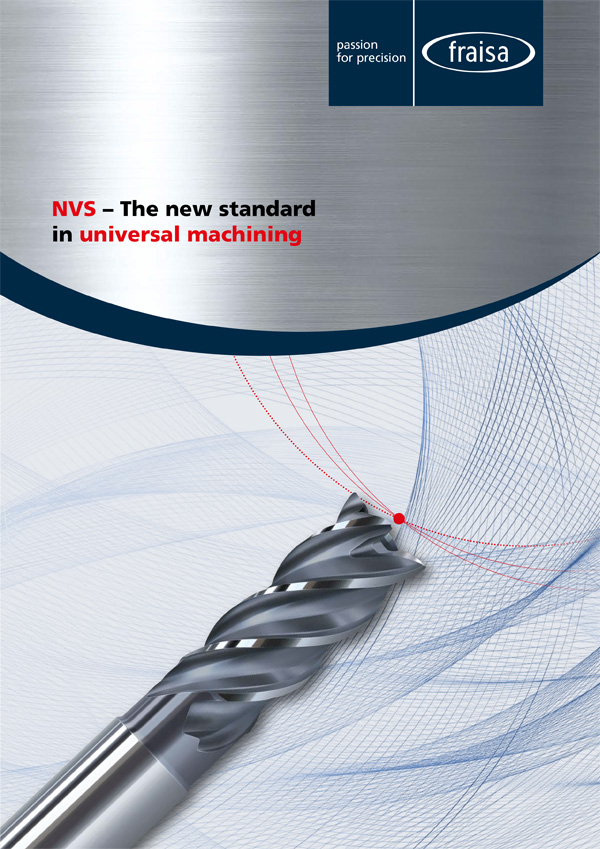

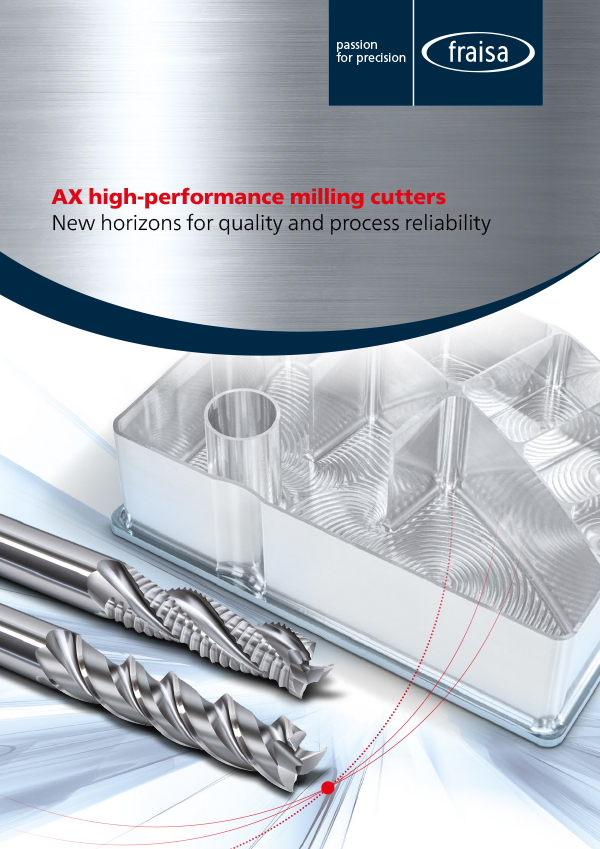

Machining

Chip-removal processes such as milling offer a high degree of accuracy and create a wide range of machining options.

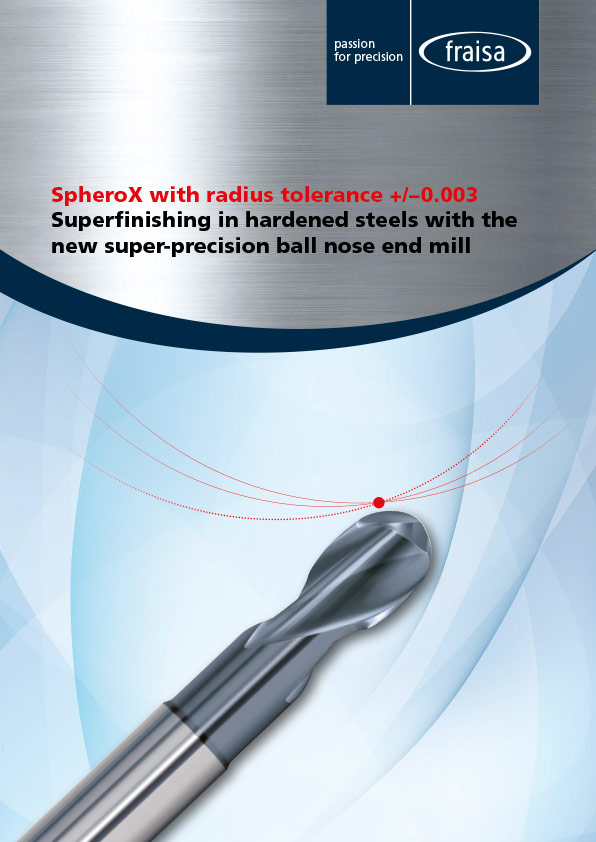

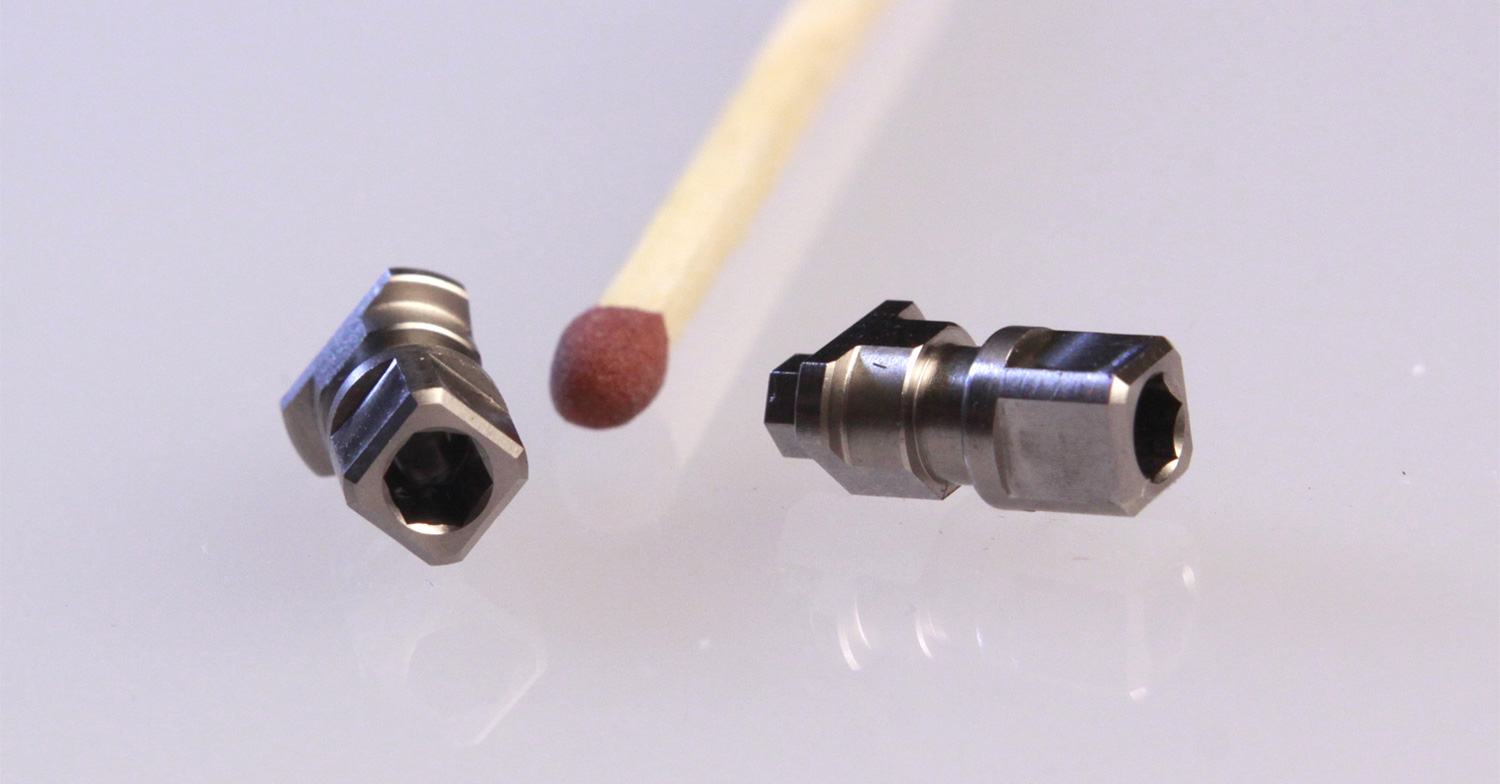

Medical technology

Precision and reliability are key to the manufacture of medical equipment – and in the end, this is vital when it comes to saving lives.

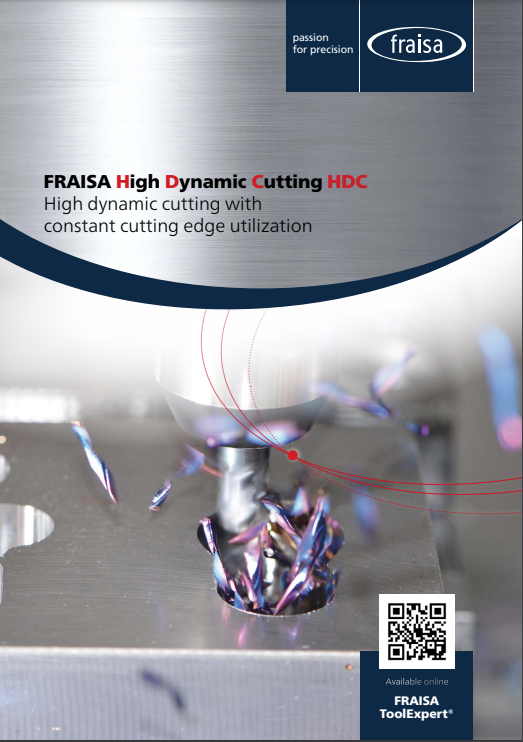

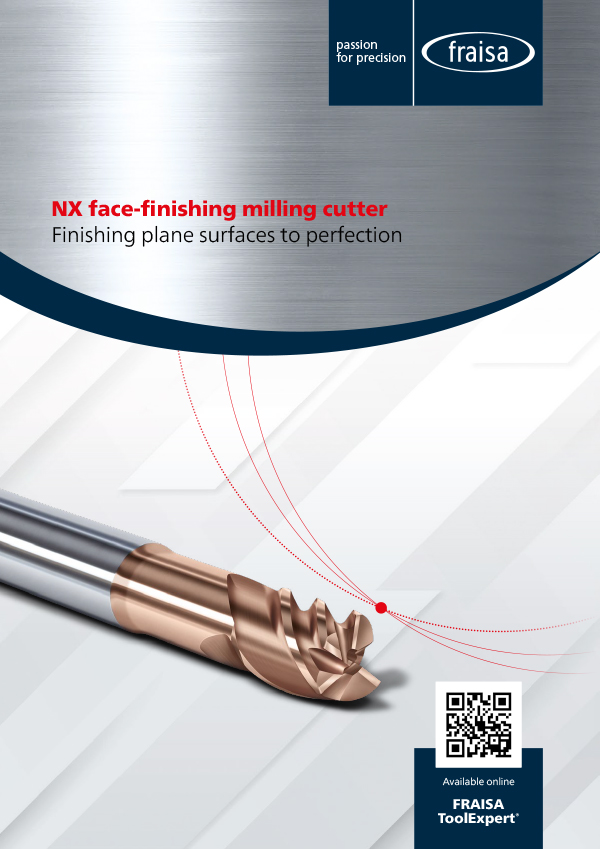

Watch industry

The fabrication of high-quality watches requires precision work and flawless surface qualities.

![[Upgrade] High-performance milling of aluminium AX-FPS](/assets/img/branchen/prospekte/AxFpsThumbDownloads_EN.PNG)